Introduction:

Tires are an essential part of our daily lives, enabling our vehicles to smoothly glide over roads and terrains. But have you ever wondered about the intricate layers that make up a tire? From the outer rubber to the inner steel belts, a tire’s construction involves several layers, each playing a crucial role in ensuring safety, performance, and durability. In this blog post, we’ll dive deep into the anatomy of a tire and explore the question: “How thick is a tire?”

The Basics of Tire Construction:

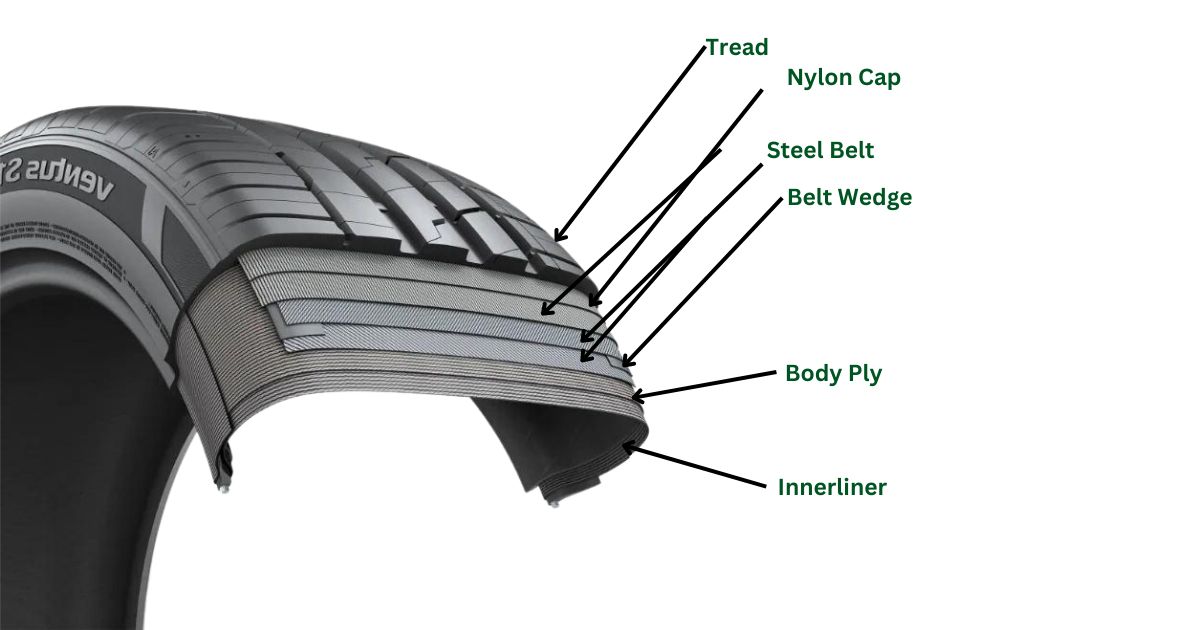

At first glance, a tire might seem like a simple rubber hoop, but its construction is much more intricate. A standard tire consists of several layers, each serving a specific purpose:

- Tread: The outermost layer of the tire that comes into direct contact with the road is called the tread. This layer provides traction and grip, allowing the vehicle to maintain control on various surfaces. Tread depth can vary based on the type of tire, its intended use, and the manufacturer’s design.

- Sidewall: Surrounding the tire’s circumference are the sidewalls. These sturdy layers protect the tire from impacts and abrasions. The sidewalls also display important information such as tire size, load capacity, and speed rating.

- Belts and Reinforcements: Beneath the tread and sidewalls are layers of steel belts and fabric reinforcements. These layers provide structural integrity to the tire, preventing it from expanding under the force of the air pressure and maintaining its shape during high-speed driving.

- Inner Liner: The innermost layer of the tire, facing the air chamber, is the inner liner. This layer is responsible for maintaining the tire’s air retention, preventing leakage, and ensuring proper inflation.

Measuring Tire Thickness:

When it comes to measuring tire thickness, it’s important to consider which layer you’re referring to. The total thickness of a tire can vary significantly depending on the tire’s size, design, and purpose. The combined thickness of all the layers mentioned above can range from a few inches for small passenger car tires to several inches for heavy-duty truck or off-road tires.

Measuring tire thickness involves assessing the depth of the tread, which is the part of the tire that comes into contact with the road. Tread depth is crucial for maintaining traction, especially in wet or slippery conditions. Here’s how you can measure tire thickness:

What You’ll Need:

- A tread depth gauge (digital or manual)

- A coin (such as a penny or a quarter)

Steps to Measure Tire Tread Depth:

- Check Tread Wear Indicators: Many modern tires have built-in tread wear indicators, also known as “wear bars.” These are small raised bars of rubber located at various points within the tire’s tread grooves. When the tread wears down to the level of these bars, it’s an indication that the tire needs replacement.

- Use a Tread Depth Gauge:

- A tread depth gauge is a tool specifically designed to measure the depth of tire tread. It’s the most accurate way to measure tread depth.

- Place the gauge flat into the tread groove. Make sure it’s perpendicular to the tire surface.

- Press down on the gauge until the base of the tool touches the tire’s tread blocks.

- Read the measurement displayed on the gauge.

- Use a Coin:

- If you don’t have a tread depth gauge, you can use a common coin to estimate tread depth. This method is less precise but can give you a general idea of your tire’s condition.

- Insert a coin into a tread groove with the coin’s edge facing down and the top of the coin facing towards you.

- If part of the coin’s edge is hidden by the tread, your tread depth is likely acceptable. If you can see the entire edge of the coin, the tread might be worn and close to needing replacement.

- Different coins have different tread depths associated with them. For example, in the United States, you can use a penny or a quarter. The Lincoln Memorial on a penny should be partially obscured by the tread, while George Washington’s head on a quarter should be similarly obscured.

Important Tips:

- Measure tread depth in several locations around each tire, including the center, inside, and outside edges. This helps you identify uneven wear patterns, which might indicate alignment or tire pressure issues.

- Check the manufacturer’s recommendations for minimum tread depth. In many places, a minimum of 2/32 of an inch (1.6 mm) is considered the legal limit for safe tire tread depth. However, for optimal safety and performance, consider replacing tires before they reach this minimum limit.

- Regularly measuring tread depth and inspecting your tires for signs of wear can help you anticipate when it’s time to replace them, ensuring your vehicle’s safety and performance on the road.

Remember that tread depth is just one aspect of tire health. Regular maintenance, proper inflation, alignment checks, and rotation are all essential for ensuring your tires perform optimally and maintain their lifespan.

Monitoring Tire Tread Wear:

Regularly monitoring your tire tread wear is crucial for your safety and the performance of your vehicle. As you continue to drive, the tread depth gradually decreases due to friction with the road, road conditions, and driving habits. Here’s how you can stay proactive about tracking tire tread wear:

- Visual Inspection: Regularly examine your tires for signs of uneven wear, cuts, cracks, or bulges. Uneven wear can be an indicator of alignment issues, improper inflation, or suspension problems. Address these issues promptly to prevent further damage and ensure your tires wear evenly.

- Tread Wear Indicators: As mentioned earlier, many tires come with built-in wear bars in their tread grooves. These bars become visible when the tread depth wears down to a certain level. When you see these bars, it’s a clear signal that your tires need replacement.

- Tread Depth Gauge: If you have a tread depth gauge, it’s a valuable tool to have in your maintenance kit. Measure tread depth regularly, and keep track of the measurements over time. This helps you identify how quickly your tires are wearing and anticipate when replacement is necessary.

Knowing When to Replace Tires:

Tire tread depth isn’t the only factor determining tire replacement. Other indicators include:

- Age: Even if the tread appears to be in good condition, tires can degrade over time due to exposure to UV rays, temperature fluctuations, and the effects of the elements. Tires that are more than six years old, regardless of tread depth, should be inspected by a professional and potentially replaced.

- Sidewall Damage: If you notice cuts, bulges, or other damage to the sidewalls of your tires, it’s a sign that they might need to be replaced. Sidewall damage can compromise tire integrity and safety.

- Performance: If you experience decreased traction, increased stopping distances, or reduced handling, it might be a sign that your tires are no longer performing optimally.

- Seasonal Considerations: For regions with harsh winters, it’s recommended to use winter tires with deeper treads during the colder months. Switching to winter tires can improve traction on snow and ice.

Factors Influencing Tire Thickness:

- Tire Type: Different types of tires, such as all-season, summer, winter, performance, and off-road tires, have varying thicknesses due to their unique tread patterns, sidewall designs, and intended usage.

- Vehicle Application: Tires designed for specific vehicles, like sedans, SUVs, trucks, and motorcycles, have different thicknesses to accommodate the vehicle’s weight, size, and performance demands.

- Load Capacity: Tires with higher load-carrying capacities often have thicker construction to withstand the additional weight.

- Speed Rating: Tires with higher speed ratings might feature reinforced layers to handle the increased forces generated at high speeds.

How to Maintain Tire:

Maintaining your tires is crucial for both your safety and the longevity of your vehicle. Here are some essential tips to help you maintain your tires:

1. Regularly Check Tire Pressure:

Keep your tires properly inflated according to the manufacturer’s recommended PSI (pounds per square inch) listed in your vehicle’s manual or on the door jamb. Underinflated or overinflated tires can lead to decreased fuel efficiency, uneven wear, and reduced handling.

2. Inspect Tread Depth:

Adequate tire tread depth is essential for maintaining traction on the road, especially in wet or slippery conditions. Use a tread depth gauge to measure the depth, and replace tires that have worn down to 2/32 of an inch (1.6 mm) or less.

3. Rotate Tires Regularly:

Tire rotation helps ensure even wear across all tires. Consult your vehicle’s manual for recommended rotation intervals. Generally, rotating your tires every 6,000 to 8,000 miles (9,600 to 12,800 kilometers) is a good guideline.

4. Balance and Align Tires:

Proper tire balance and alignment prevent uneven wear and improve vehicle handling. If you notice vibrations at certain speeds or uneven tire wear, it’s a good idea to have your tires balanced and aligned by a professional.

5. Check for Damage:

Regularly inspect your tires for cuts, punctures, bulges, or other signs of damage. If you find any, have them inspected by a professional. Damaged tires can lead to sudden failures while driving.

6. Maintain Proper Load Capacity:

Overloading your vehicle can strain the tires, leading to premature wear and reduced performance. Check your vehicle’s load capacity rating and avoid exceeding it.

7. Drive Smoothly:

Aggressive driving behaviors like hard braking, sharp turns, and rapid acceleration can wear out your tires faster. Drive smoothly and anticipate stops to minimize unnecessary stress on your tires.

8. Avoid Overloading:

Exceeding your vehicle’s weight limit can put excessive stress on your tires, leading to quicker wear and potential blowouts. Be mindful of your vehicle’s load capacity and avoid overloading it.

9. Store Tires Properly:

If you use seasonal tires, make sure to store the unused set in a cool, dry, and dark place. Use tire covers to protect them from sunlight and ozone damage.

10. Regular Maintenance Checks:

Incorporate tire maintenance into your regular vehicle maintenance routine. Regularly inspect and maintain other components of your vehicle (e.g., suspension, brakes) to ensure they don’t contribute to uneven tire wear.

11. Replace Tires When Necessary:

Even with proper maintenance, tires have a limited lifespan. Generally, tires should be replaced every 6 years, regardless of their tread depth. If you notice significant wear, damage, or your tires are older, it’s time to replace them.

FAQ:

How Thick is a Tire?

Tire thickness is generally measured by its tread depth, which can vary based on the type and brand of the tire. New tires typically have a tread depth of around 10/32 to 12/32 of an inch (approximately 8 to 10 millimeters). However, the tread depth will decrease as the tire wears down with use.

How thick is the sidewall of a tire?

The thickness of a tire’s sidewall varies depending on the tire’s size, type, and manufacturer. On average, sidewalls can be around 6% to 10% of the tire’s width. For example, in a tire with a width of 225 millimeters (mm), the sidewall thickness might range from about 13.5 mm to 22.5 mm. However, this is a general guideline, and actual measurements can differ. Sidewalls provide structural support, impact absorption, and flexibility for the tire. It’s essential to refer to the tire’s specifications provided by the manufacturer for accurate sidewall thickness information.

How thick is a car tire?

The thickness of a car tire varies depending on the type and size. Generally, the tread depth ranges from 8 to 15 millimeters (0.31 to 0.59 inches), while the overall tire thickness, including layers like the sidewall and belts, can range from around 170 to 270 millimeters (6.7 to 10.6 inches).

Is a 295 tire the same as a 33?

No, a 295 tire is not the same as a 33. The number refers to different aspects: 295 represents the width of the tire in millimeters, while 33 indicates the tire’s outer diameter in inches. They are distinct measurements used to describe different characteristics of the tire.

How wide is a 295 tire?

A 295 tire width is approximately 295 millimeters or about 11.61 inches across the tread surface. It’s an essential measurement that affects grip, handling, and overall performance.

Can i use 75 tires instead of 70?

Yes, you can use 75 tires instead of 70, but it’s essential to consider their compatibility with your vehicle. The numbers represent aspect ratios, impacting tire height. Consult your vehicle’s specifications or a professional to ensure safe fitment without affecting performance, speedometer accuracy, or handling.

Can i put 15 tires on 14 rims?

No, you cannot put 15-inch tires on 14-inch rims. The tire size must match the rim size for proper fit and safe operation of the vehicle. Using mismatched sizes can result in handling issues, tire damage, and compromised safety.

How wide is a 245 tire in inches?

A 245 tire is approximately 9.65 inches wide.

What does 21 inches look like?

21 inches appears as a length slightly longer than a standard school ruler, about the width of a large laptop screen, or approximately half the height of an average bicycle wheel.

Are 305 tires the same as 33?

No, 305 tires are not the same as 33. The numbers refer to different aspects. “305” is the tire width in millimeters, while “33” represents the tire diameter in inches. They indicate distinct measurements of a tire’s size, affecting performance, fitment, and appearance on a vehicle.

Can i put 65 tires on 60?

Yes, you can put 65 tires on rims designed for 60 tires, but it’s not recommended. It might affect handling, speedometer accuracy, and safety due to the differences in tire size. Stick to the manufacturer’s recommended tire size for optimal performance and safety.

Conclusion:

In the world of tires, thickness is not a one-size-fits-all measurement. The layers that make up a tire work in harmony to provide safety, performance, and longevity. The next time you examine a tire, you’ll know that its thickness is a result of careful engineering, taking into account factors such as tire type, vehicle application, load capacity, and speed rating. Whether you’re navigating city streets or tackling off-road adventures, the intricacies of tire construction ensure you have a safe and comfortable journey.